Eco-Innovative Prototypes: Collaboration with OSIRYS, Part 2

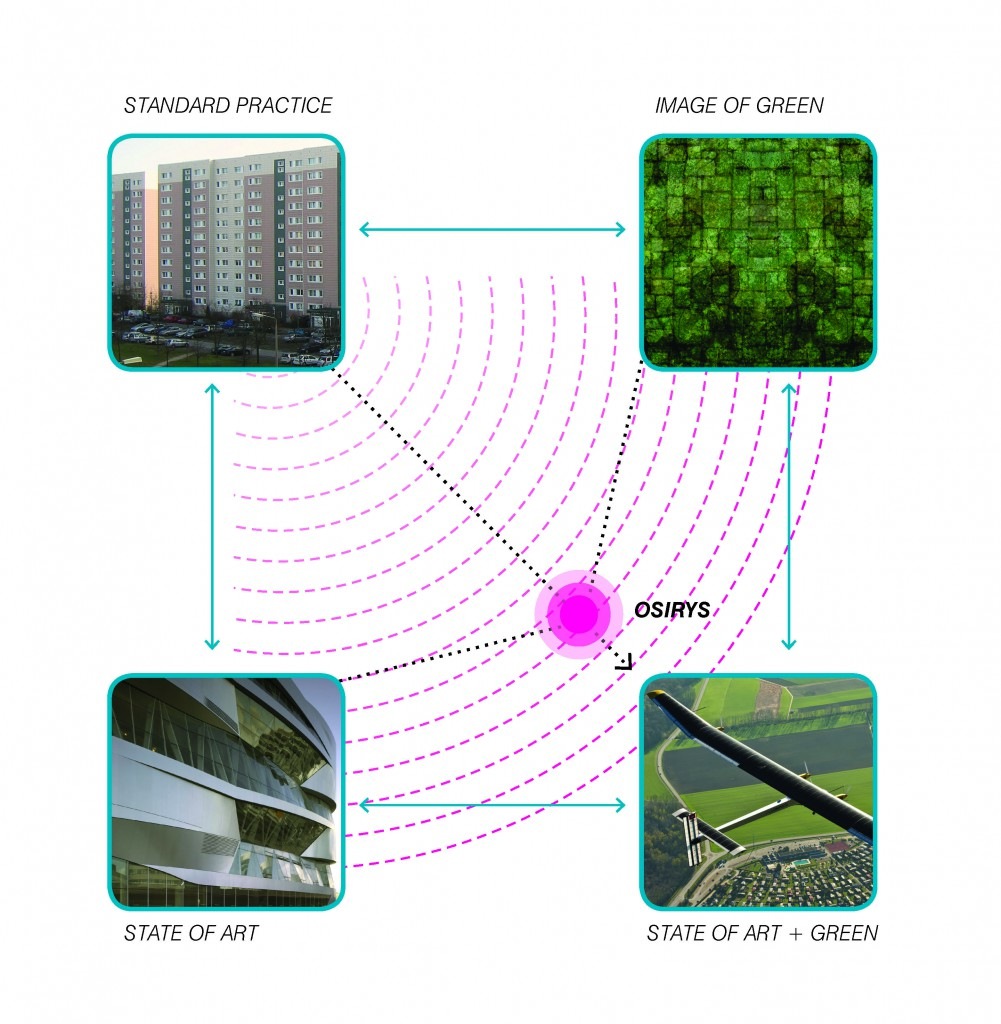

This article provides an update on the status of the OSIRYS project. Now in its third year, the OSIRYS consortium is creating prototypes for building systems designed in response to a call to improve indoor air quality by the Seventh Framework Programme for Research and Technological Development. This programme (FP7) is the EU’s primary system for funding research in the European Union from 2007-2013. In short, UNStudio and fellow partners of OSIRYS aim to promote the development of solutions to reduce hazards in the built environment. Such hazards are commonly triggered by volatile organic compounds (VOCs), formaldehydes and other toxic gases highly prevalent in contemporary construction materials that release particulates and fibres into the air we breathe.

The main strategy of the OSIRYS consortium is to develop eco-innovative building materials and systems that can provide a healthier indoor environment. We think there are two paths to doing so. First, we are replacing the contemporary construction materials and products producing hazardous contaminants with bio-based materials and products. Second, because we understand that all hazardous materials cannot be replaced overnight, we are further developing available photoactive compounds to absorb VOCs, formaldehydes and other chemicals, in addition to destroying bacteria in relatively low artificial light levels.

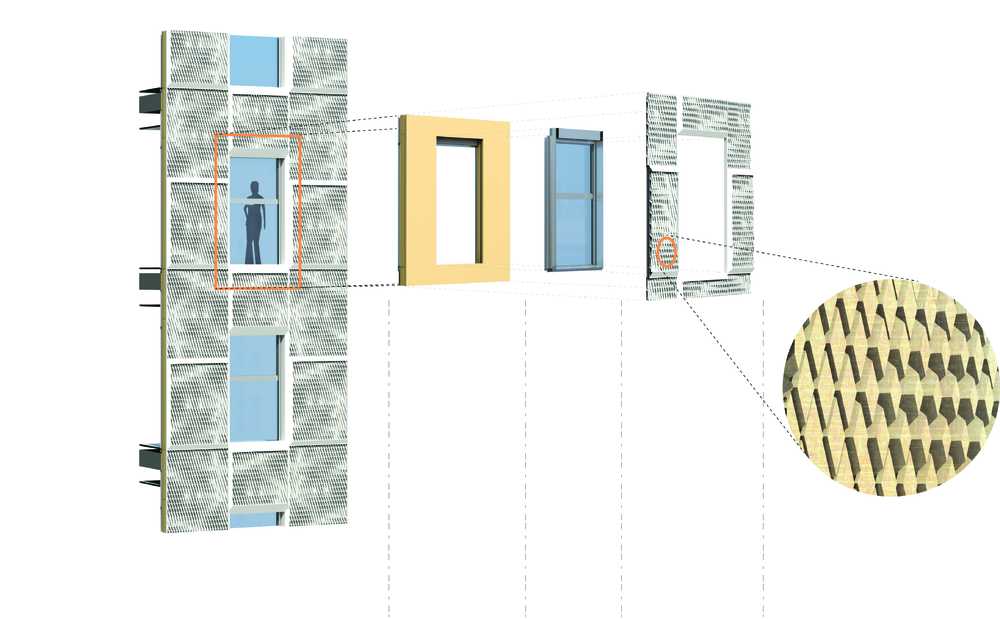

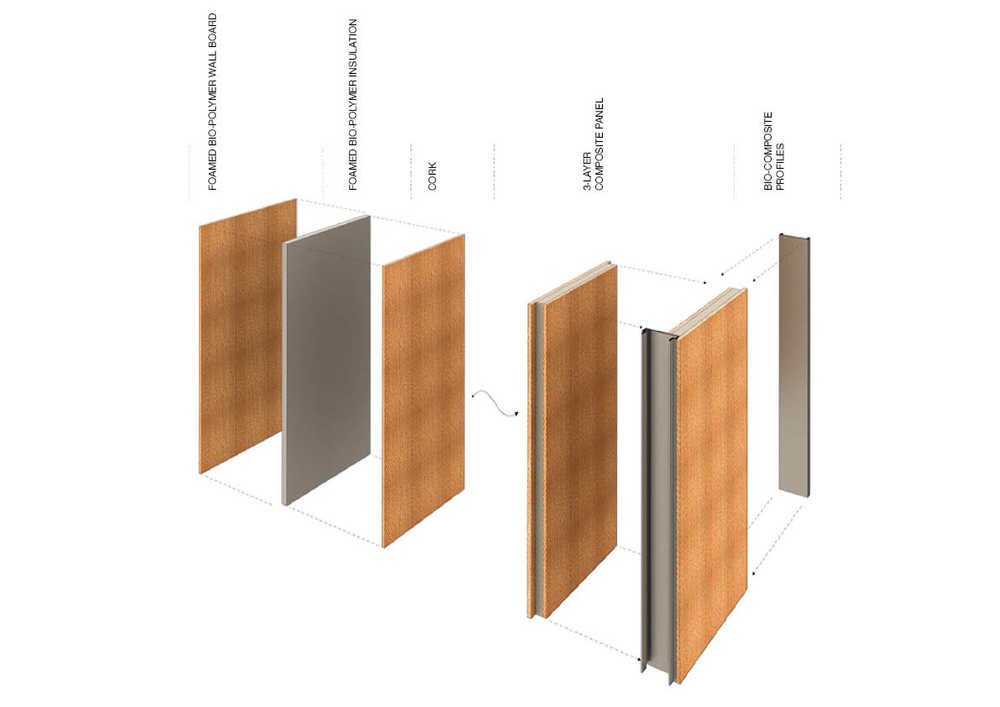

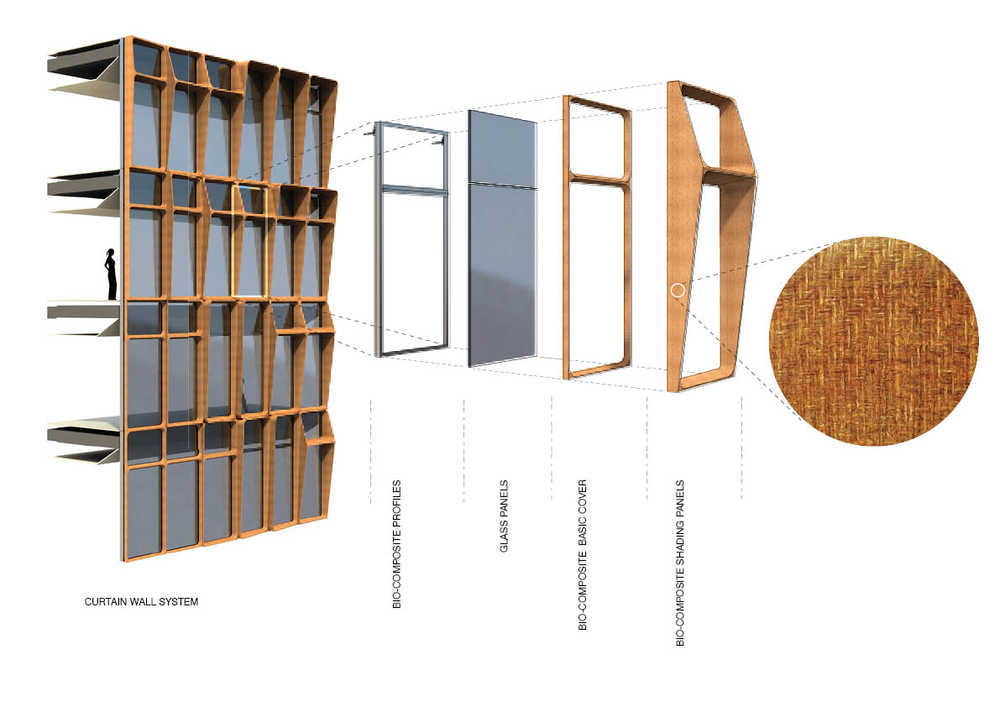

To accomplish this, the OSIRYS project is structured toward the creation of four products: a curtain wall system, a multi-layer facade system, windows, and interior partition walls. As the primary finishing elements of a building, these products are positioned to make a great impact on the indoor air quality and the building construction market. This may sound like a simple task, but in order to develop these new products, the consortium’s work must include the development of new materials: a multifunctional photo-active coating, light foam panels (to replace gypsum wallboard), cork panels for acoustic absorption and fire resistance, fire resistant biocomposite panels, weather resistant biocomposite panels for exterior cladding, high mechanical performance biocomposite profiles and bio-adhesives to hold it all together.

The combination of these materials into products and the procedures required to introduce them to the construction market requires highly innovative solutions. By providing some examples of how several of the aforementioned materials will be integrated into the four OSIRYS products, we hope to provide an understanding of how we plan to achieve the stated advancements. For instance, and most ubiquitously, the multi-functional photo-active coating is the finish of our interior partitions and the interior faces of the multi-layered and curtain wall facade systems. The coating comprises application of latex house paint and will adhere cleanly to the extruded lightweight foam panels. These panels will serve to replace the three-part process (paper-gypsum-paper) of typical gypsum wallboard with a single extrusion of foamed bio-polymer. The lightweight foam panels are integrated into the OSIRYS products, but could easily become a marketable product of their own.

The three facade products (multi-layered wall, window and curtain wall) will share many of the same materials, while differing in design and engineering approach. Some of the most distinctive components to be engineered are the structural profiles in each of these products. Our first graphene-reinforced protrusions are being produced and tested at lab scale, and full-scaled simulations conducted. The multi-layered and curtain wall systems will also share the exterior panels as a component system.

The end goal of the OSIRYS project is to bring these products up to a technology readiness level of '7', which is a demonstration of pilot production. For this we target the integration of the products in two buildings in Europe: one in Spain and the other in Estonia. For optimal performance it is important to test the products in the disparate climates of Europe.

The OSIRYS consortium comprises a partnership between UNStudio, Tecnalia, Acciona, VTT, Fraunhofer, AIMPLAS, IVL, Townhall of Malmo, Tecnaro, Netcomposites, Omikron, Plastil, Amorim Cork Composites, Enar, Bergamo Tecnologie, Visesa, Sicc, and Collanti Concorde.

UNStudio Team: Ger Gijzen, Rob Henderson, Filippo Lodi