Photovoltaic Modules: Collaboration with Construct PV, Part 2

This is the second of two posts concerning the Construct PV project. The project aims to improve photovoltaic (PV) modules through architectural research with a number of international science and industry partners. The research has received funding from the European Commission's Seventh Framework Programme (FP7/2007-2013) under grant agreement n° 295981. The goal of the project is to convert the standard industrial PV module into a product that offers greater design flexibility to meet the needs and requirements of different socio-geographic areas. A further aim of the research is to create a design catalogue with aesthetic and cost-effective choices for PV modules – and bring these possibilities to the European market, together with our partners in the PV manufacturing industry.

Various small and large scale mock-ups are currently in production for the Construct PV research project. These mock-ups explore the integration of PV in both roofs for large scale installation and production, and in facades testing the compatibility of PV with various facade types.

This small scale mock-up specifically deals with the integration of PV on the roof. This 1:1 scale model will be tested and monitored in Lugano, Switzerland, before being evaluated, improved and produced for a large-scale installation in Athens, Greece.

For this small scale mock-up, a range of typical glazed facades is displayed to show the compatibility of PV with various facade types. The detailing in the mock-up is developed to target seamless integration of PV in various facade designs and geometries. On a more detailed level this setup also displays variations of PV-module cell designs and patterns in the layering of the PV module. The mock-up is installed on a mobile platform to allow transportation to trade fairs and exhibitions and will be exhibited at a number of fairs in the coming year.

The small scale facade setup consists of a standard curtain wall, with Mosaic PV integrated in the opaque spandrel panel; a retrofit of the Zueblin Z3 building facade, an office building used by Zueblin in Stuttgart, Germany; the Education Executive Agency and Tax Office facade in Groningen, The Netherlands, whose horizontal shading fin was adapted to incorporate PV capability; and the Hanwha Headquarters facade, produced by leading environmental and PV technology manufacturers. This UNStudio design is currently being used for retrofitting an office building in Seoul, South Korea.

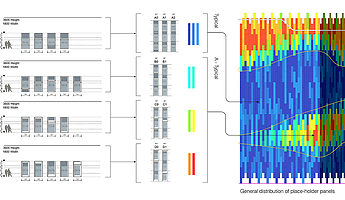

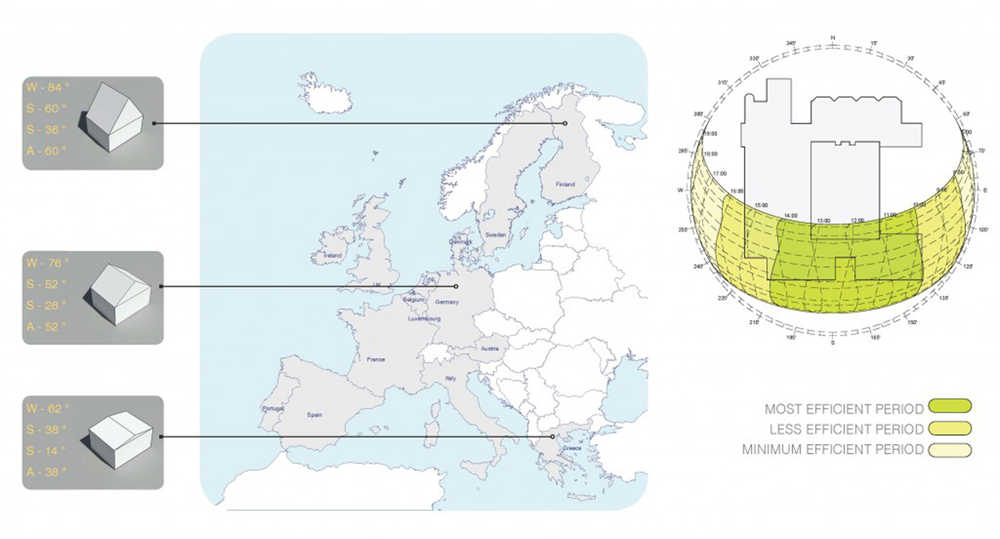

The challenge for this large scale mock-up is to provide an architectural design for a PV product that is flexible enough to adapt to various climatic (relating to sun inclination) and typological (relating to roof geometry) situations throughout Europe. The building site for the mock-up is located on the roof of a university building on the campus of the National Technical University in Athens, Greece.

The basic product, resembling a glass shingle, can be used as a design element that is flexible enough to adapt to the different identified situations - representing a range of roofs from the high north in Norway to the deep south in Greece.

For the best electricity production output, the PV shingle on the roof surface is positioned to match the angle of solar radiation. The main difference for the different latitudes is the steepness of the inclination of the sun during the day and year in the mentioned countries.

The large variety of roof typologies in the European Union results in a requirement for the PV-product to be flexible enough to cover a wide range of geometries, from angled to convex and concave.

The roof installation consists of one sculptural form combining a selection of eight design surfaces representing the identified geometries both in terms of typology and inclination. The combined sculptural design results in one integrated whole, which is both weatherproof and fully PV capable.

The eight roof surfaces, which vary in angle, typology, size and surface finish (metal or PV), have a distinctive pixelated pattern. This pattern aims to further incorporate the PV shingles with a mix of regular metal shingles, demonstrating a full integration of the PV product within this collection of roof types.

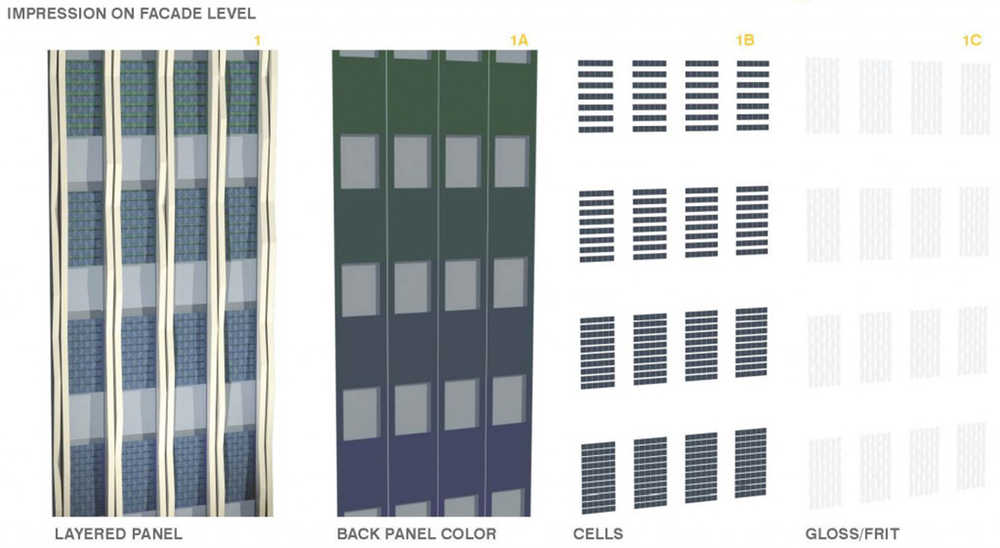

The facade of the Z3 building on the Zueblin Campus in Stuttgart, Germany was chosen as the target for a retrofit of an existing building envelope. The Z3 building is an existing office building used by Zueblin, a large contractor based in the south of Germany. The building already has a large number of sustainability measures implemented. The request was to retrofit the facade with PV capability while complementing the existing design aesthetics of the facade. The existing facade was designed by MHM architects in Vienna, who cooperated with UNStudio to adapt the facade design to allow PV capability.

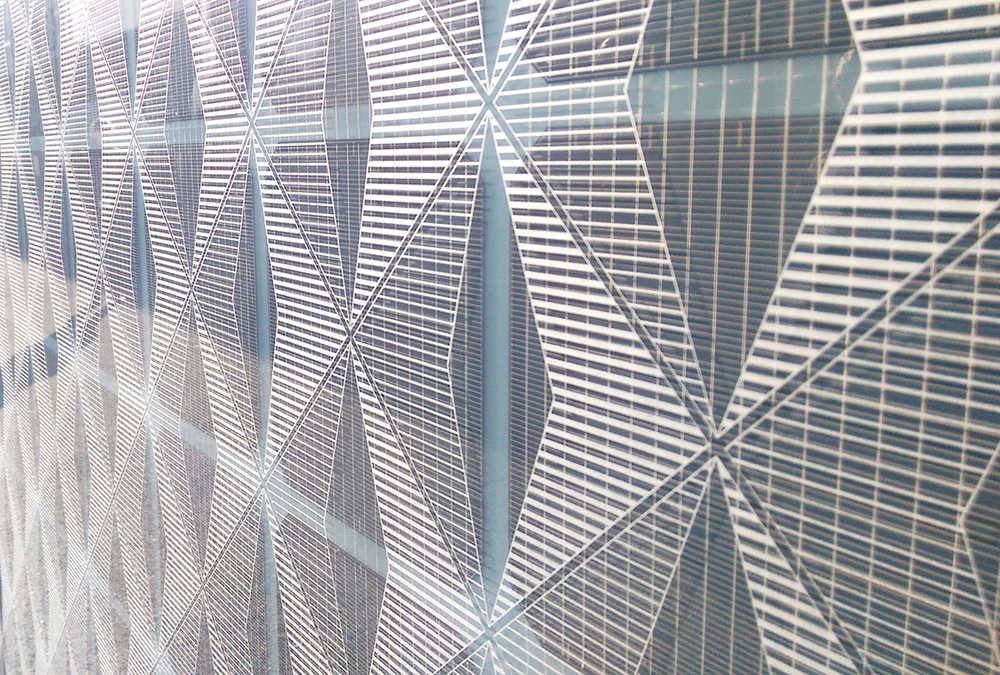

The aim of the design for the existing building was to use PV while maintaining the pronounced existing geometry in the form of wooden fins and refining it with an additional subtle layer of PV reflecting the facade’s appearance on a more detailed level.

The aim of this concept was to replace the original dark anthracite hard glass front panel with a transitional design both in terms of colour and in PV, ultimately to deliver a more vibrant, integrated design layer reflecting the geometry of the vertical and angled wooden lamellas.

In the middle of the south-facing facade, the silkscreen pattern is designed to be dense and the play between pattern and PV appears most vividly. Moving from the centre to the corner of the building, the patterned PV opens up and the colour of the facade starts to match the existing colour on the east and west facade, which will not be altered.

The chosen colours for the glass back panel are of a darker colour range to match the dark colours of the existing spandrel panels. The silk screen on the front panel reflects the angular nature of the lamellas on a more refined scale.

The pattern design is engineered to allow as much solar radiation as possible to reach the PV cells behind. The effective coverage of the silk screen is between 10 and 15%, which will lead to only limited reduced output efficiency, again showing the fine balance between cost and effect in the design of architectural PV modules.

An alternative fabrication technique shown in one of the prototypes below is the sandblasting of the front panel. This technique was used for the early prototyping of the PV modules, to be able to test various designs.

The retrofitting of the large scale facade of the Z3 building is planned for completion in early 2016. The final goal for the south facade is to provide an enhanced layered design integrating colour and PV, resulting in an innovative and long-term facade solution.

UNStudio Team: Nuna Almeida, Ger Gijzen, Rob Henderson

Partners:

Züblin, Germany (General Contractor and Project Management)

D’Appolonia, Italy (Market Analysis and Project Management)

Fraunhofer-ISE, Germany (PV Research Institute)

NTUA, Greece (Technical University)

AMS, Greece (General Contractor)

SUPSI, Switzerland (University of Applied Sciences)

ENEA, Italy (PV Research Institute)

TU Dresden, Germany (Technical University)

Meyer Burger, Switzerland (PV Manufacturer and PV Production Line Manufacturer)

Tegola Canadese, Italy (Roofing Manufacturer)