Study: TwoFour54 Double-Skin Facade

During the Design Development phase of the TwoFour54 Media Zone 1 project UNStudio, along with Buro Happold Physics, MEP and Facades Engineering, developed a complete strategy for the design of the double-skin south facade of the office towers. Clarity of concept and some clever detailing and engineering led to this groundbreaking design.

Goals

From the competition phase of the TwoFour54 Media Zone 1 project the double-skin facade (DSF) was an important feature for the design. It represented the possibility of attaining three key goals: an exceptionally taught glass surface, high environmental quality, and the implementation of media lighting. All of these factors are to give value to the project as an important landmark in Abu Dhabi and the larger world.

The DSF is a sealed external shading device that is ventilated using spill exhaust air from the podium HVAC systems. It performs to a high standard in relation to comfort, and quality and quantity of light, offering a healthy and productive workplace. It consumes between 13 and 16% less energy than a high performance single skin system. It is easier to maintain than shading devices exposed to the elements, and this protection will extend its longevity by more than two times. Regular maintenance and replacement of external layer of the facade can be done without disruption of the building activities. The integration and maintenance of media lighting on the cavity is more advantageous and flexible than in a single skin system, and the balance between reflection and transparency of the outer skin achieves the desired level of exposure of the TwoFour54 towers' activities.

The TwoFour54 towers with the double-skin facade reach levels of performance rarely attained on a project of this scale and high profile in the Middle East. The capital cost difference between the two systems can be paid in 30 years, but the added value of the different qualities of the double skin facade is that the design can become a calling card for TwoFour54 and a beacon for sustainability and sustainable innovation around the world. That is the conclusion. There is not one overwhelming advantage of or argument for the DSF, but there are several significant benefits that make this an essential feature of the development. That, though, is just the beginning of the story of the DSF.

Assembly

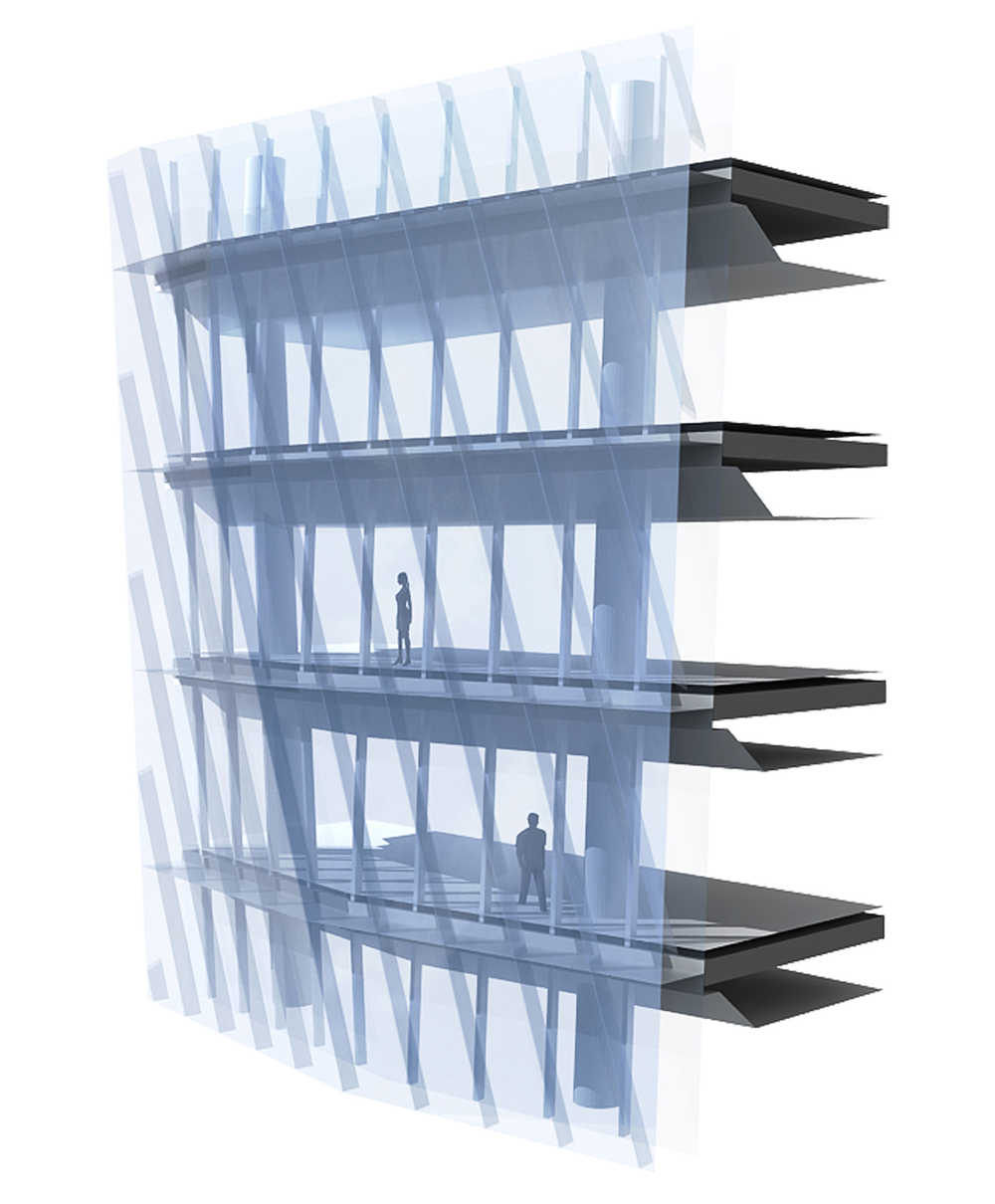

The basic desires required of a double skin facade of any type is that it provide greater transparency and provide a thermal buffer for the comfort of those working inside. The DSF surely provides for these desires and more in an innovative and elegant way.

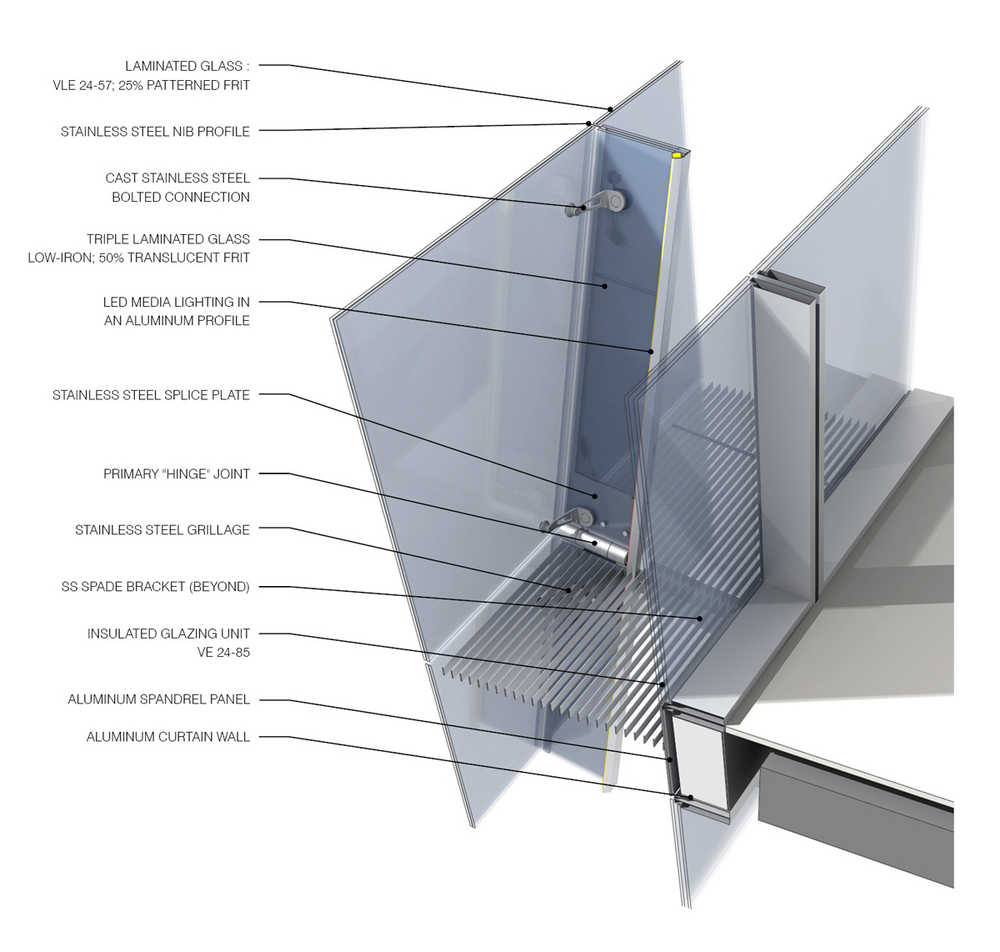

The external layer of the envelope acts as a glass external shading device. That is to say that it is not the primary weather barrier and provides shading to the space inside. Because it is not the primary weather or thermal barrier we were able to reduce the joint sizes and use laminated glass. This gives us the taught screen effect that we are looking for. The coating and frit on the glass give the initial layer of protection against solar radiation (approximately .3SHGC).

The support of the external laminated glass goes further to support this effect. Custom bolted connections and stuctural glass limit to nearly non-existent the appearance of the surface’s support from the exterior. The glass fins are also fritted, provided the second layer of protection against solar radiation. Mounted at the back of the strutural glass fins is the aluminum housing and LED fixtures for the media lighting.

The middle layer of support is within the semi-conditioned plenum space between the two layers of glass. The stainless steel fittings, glass fins and LED lighting are within this plenum. In fact, because of the clients desire for media lighting, one of the strong arguments for the cavity is that the LEDs require a max 60deg celcius which was not possible if they are directly exposed to the intense Abu Dhabi sun. It is in this layer where the most complex components of the DSF are assembled. The glass fins are connected by stainless steel splice plate and ‘hinge joint’ to the main support spade bracket to the inner layer curtain wall. The hinge joint allows more repetition from tower to tower where the angles of glass vary. The spade bracket also supports steel grills. The grills are necessary for maintenance access, but then serve as additional one meter-deep sun shades for the offices inside. They in fact become the most effective layer of solar radiation protection, and allow consistent pressure of the air coming up from the podium below.

The inner layer of the DSF is a simple curtain wall. The only eccentricity is that the panels are designed to the angles of each tower’s facade. In fact, the glazing of the inner layer has a very low level of solar radiation protection. To meet the Estidama requirements this coating is not required, but it does provide some addtional comfort and reduces the reflectivity of the glass. Herein is the small, but key innovation of the DSF: the inner layer curtain wall is used mostly for its u-value not for shading. Basically, the inner layer is only keeping out the heat built up in the plenum, for which an IGU is most effective. Additionally, the spade bracket is connected into the sides of the curtain wall units as a typical external shading device. This only requires that the spandrels don’t have glass, but this aesthetic problem is already solved with the external layer.

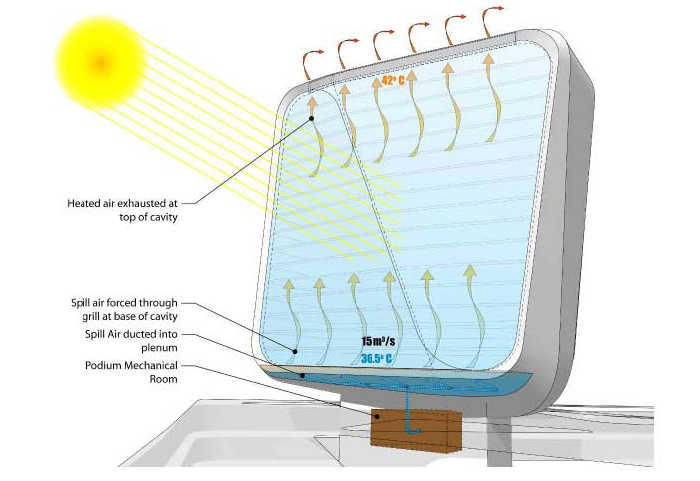

As mentioned above air rom the podium HVAC system is ‘spilled’ into the DSF. This is another subtle innovation: that the DSF is just a fancy exhaust plenum for the podiums. This provides sufficient for the cooling of the cavity to reduce the load on the inner layer and allow the LEDs to function. Over the course of the year, for 90% of the time the pressure of the air as it heats up and rises is sufficient to maintain air flow for ventilation of the DSF cavity. 10% of the time fans will be required to maintain air flow. While it is a bit of a penalty, the energy use for the fans, though, is included in the overall 13% energy savings through the DSF.

This fancy exhaust plenum requires some careful consideration at its base and head. Three topics were important in the consideration of these details: the surficial continuity of the frames from the outside, 50% open area vs. strength for maintenance, and keeping out the dust. The appearance of surficial continuity meant that we wouldn’t use the typical grills at the base and head of the facade. GRC (the material of the exterior) was deemed to be too brittle when so highly perforated, so we went with perforated aluminum, coated to match the external finish. 50% perforated aluminum is also not so robust, so the finish is composed of demountable panels for acces to the spill air plenum below and the ventilation cavity above. For maintenance purposes the panels at the head of the facade are only aesthetic. The main filter for the problematic Abu Dhabi dust in a vertically oriented mechanical weather louver mounted several meters away on the roof.

Media Lighting

As one of the main client requirements of the project, the media lighting becomes a significant feature of–and argument for–the DSF. For the most part the media lighting is at a low, atmospheric resolution. This allows for a projection method of lighting. The LED strips are mounted in a custom extruded aluminum housing, and directed to the laminated glass of the external layer. The fritting that during the day provides shading at night accepts the light from the LEDs like a screen. Eventually, the LEDs are easily maintained from the DSF cavity.

Payback

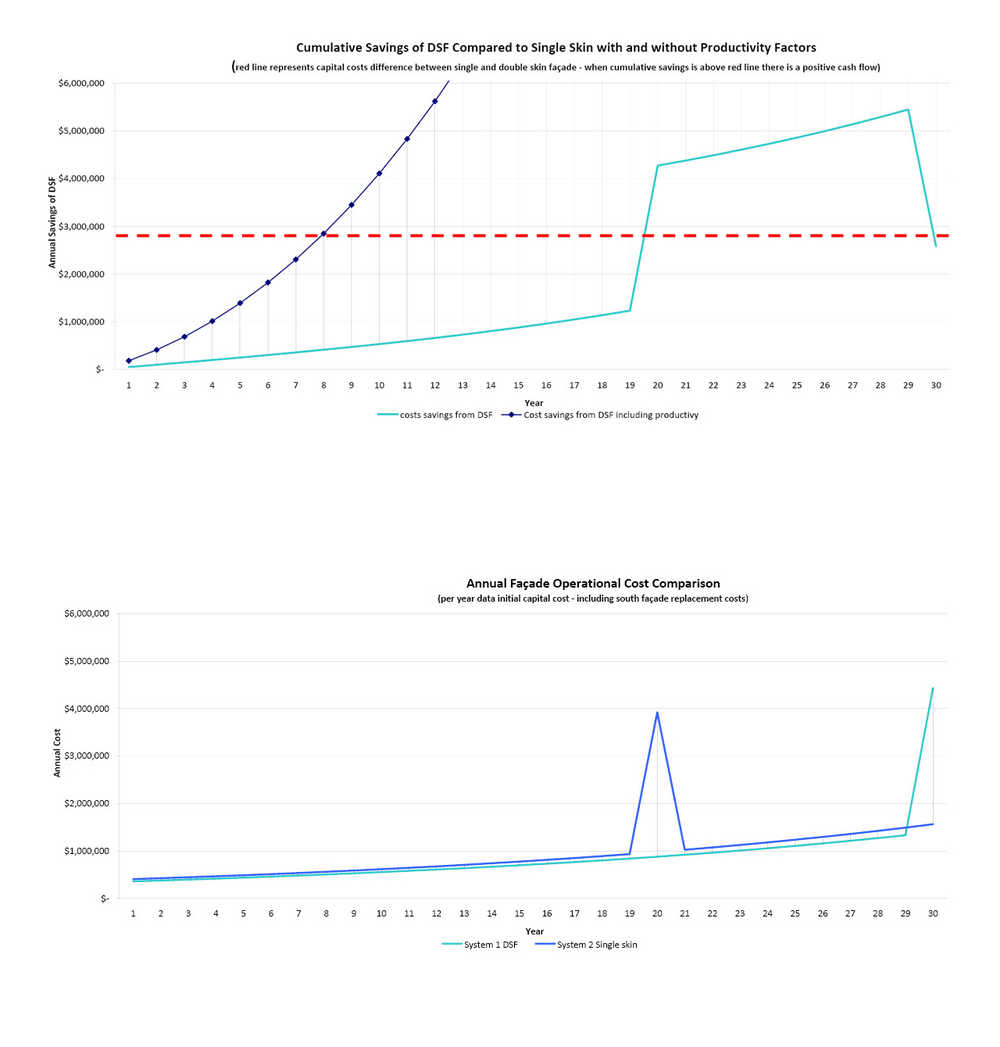

To support the aesthetic and up front environmental arguments for the DSF, we engaged with Buro Happold into an extensive cost benefit analysis. With an understanding that a glass envelope was the base desire of the client, the basis of this analysis is a comparison of the DSF to a single layer curtain wall assembly that would also meet minimum Estidama standards of .25 SHGC. The beginning of which is capital cost comparison here where the primary figures are highlighted. The cost benefit analysis included a quantification of capital cost, maintenance cost (including replacement), productivity costs and energy costs.

As we saw the capital cost from the previous section, what is important now is the client’s yearly expenditure. Maintenance of the DSF is by definition more expensive as a yearly rate, but the benefit comes in the long term when one becomes aware that by protecting the inner curtain wall from the elements you may increase its lifespan up to 3 times (to 60 years), whereas a typical curtain wall would require replacing after 20 years. This is reflected in the jump in the lower line of the graph at bottom right. The most controversial area of our investigation was the client savings stemming from emplyee comfort and productivity. As you might see in the spread sheet to the right, worker comfort it based on internal glass temperature. This is tracked as PPD (percentage of people dissatisfied), and counted as productivity loss when the percentage rises above 15%. The DSF allowed 45% fewer lost hours of productivity versus the typical curtain wall.

These two factors became the location of the greatest long term savings for the client. The DSF will has been calculated to save 13% on overall energy use. This number would be much more significant if it weren’t for the incredibility low energy costs in Abu Dhabi; European kw/h rates are roughly three times that of Abu Dhabi. Nonetheless, we are able to save approximately $45,000/year in energy costs alone.

UNStudio Team: Ben van Berkel, Astrid Piber with Nuno Almeida, Albert Gnodde, Andreas Bogenschuetz, Ariane Stracke, Chiara Marchionni, Jeong Eun Choi, Florian Licht, Ger Gijzen, Gustav Fagerström, Iris Pastor, Jaap Baselmans, Jaap-Willem Kleijwegt, Jay Williams, Ka Shin Liu, Kristin Sandner, Margherita Del Grosso, Martin Zangerl, Mirko Bergmann, Patrick Noome, René Rijkers, Rob Henderson, Silvia Filucchi, Stefano Rocchetti, Thomas van Bekhoven

Buro Happold Participants: Matthew Herman, Roberto Fabbri, Erik Verboon