Translucent Concrete: Collaboration with BrightWall

After a two-year-long research and design process, the BrightWall project has been completed. UNStudio will now investigate key aspects of the panel design and manufacturing process. Based on the EU’s Seventh Framework Programme for Research and Technological Development call for energy savings in buildings, the BrightWall project researches fibre optics-based translucent concrete. The goal of the research is the development of a fully insulated facade system that will allow for controlled daylight to pass while lowering in the heating load in a building. The partners in the nine-member consortium range from concrete manufacturers to architects to fibre optics specialists.

Approximately 15% of electricity consumption in the EU comes from lighting. This figure is much higher than it might be, considering that more than half of European artificial light is currently emitted from ineffective incandescent light bulbs. In addition, more than 90% of indoor working environments are illuminated by fluorescent lighting during the daytime, which in addition to consuming electricity, also produces heat and may require other forms of climate control on sunny days.

For this reason, as set out in the energy end-use efficiency and energy services directive (2006/32EC), the EU has a goal of reducing electricity consumption by 9% by 2017. The transfer of daylight into buildings can significantly impact energy efficiency gains in lighting and possesses, therefore, a high potential for both the regulation of indoor climate and for innovation in architecture and product design.

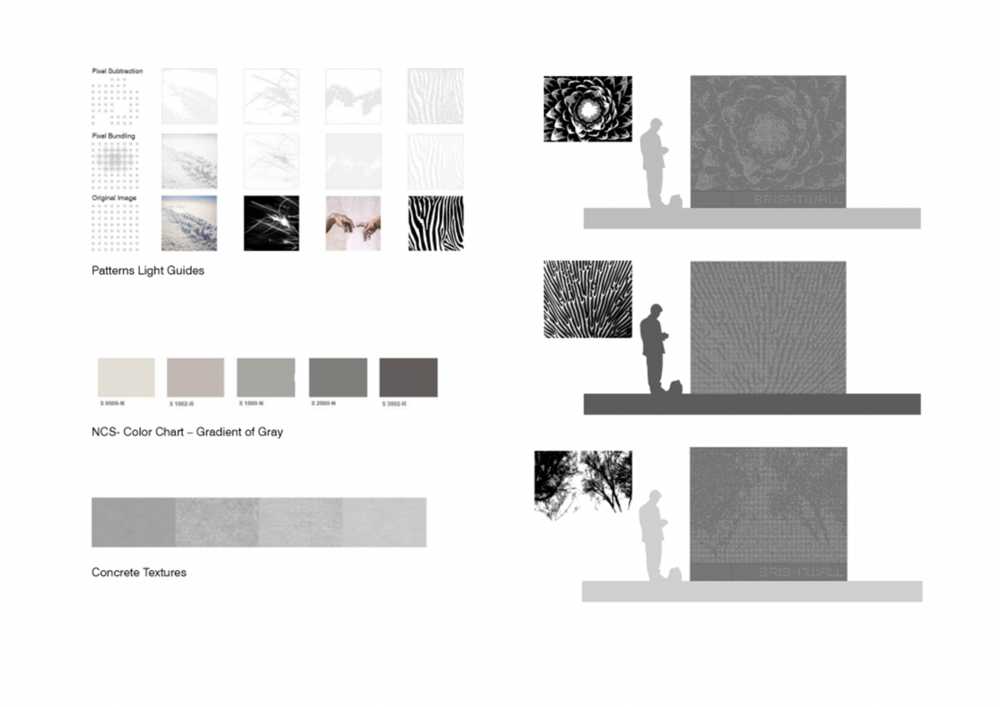

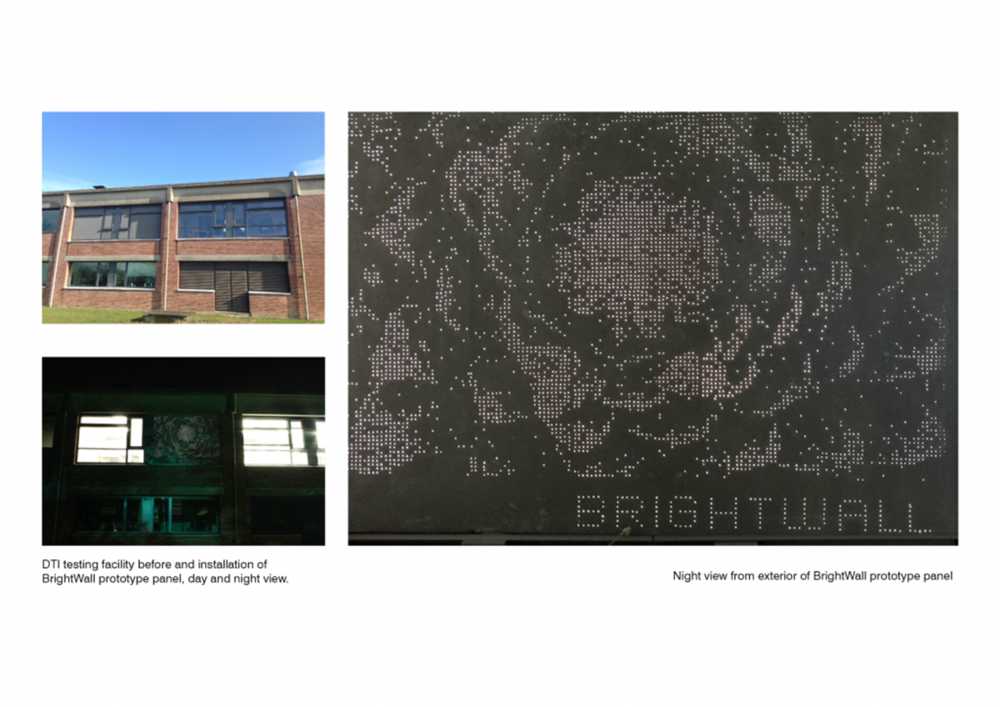

BrightWall is a new building material – translucent concrete in the form of an insulated sandwich panel – which has a strong architectural and aesthetic potential. The material combines great strength with precisely embedded optical fibres and strong thermal performance. The new system can be applied as passive and daylight-transferring exterior walls in new buildings and renovations. Modular construction has proven to be the choice for many buildings due to all the associated advantages, namely its cost-effectiveness and the fact that buildings can be constructed in up to half the time, when compared to conventional construction. Precast concrete sandwich panels, comprised of two concrete faces and a fully insulated core, can be used on most types of buildings.

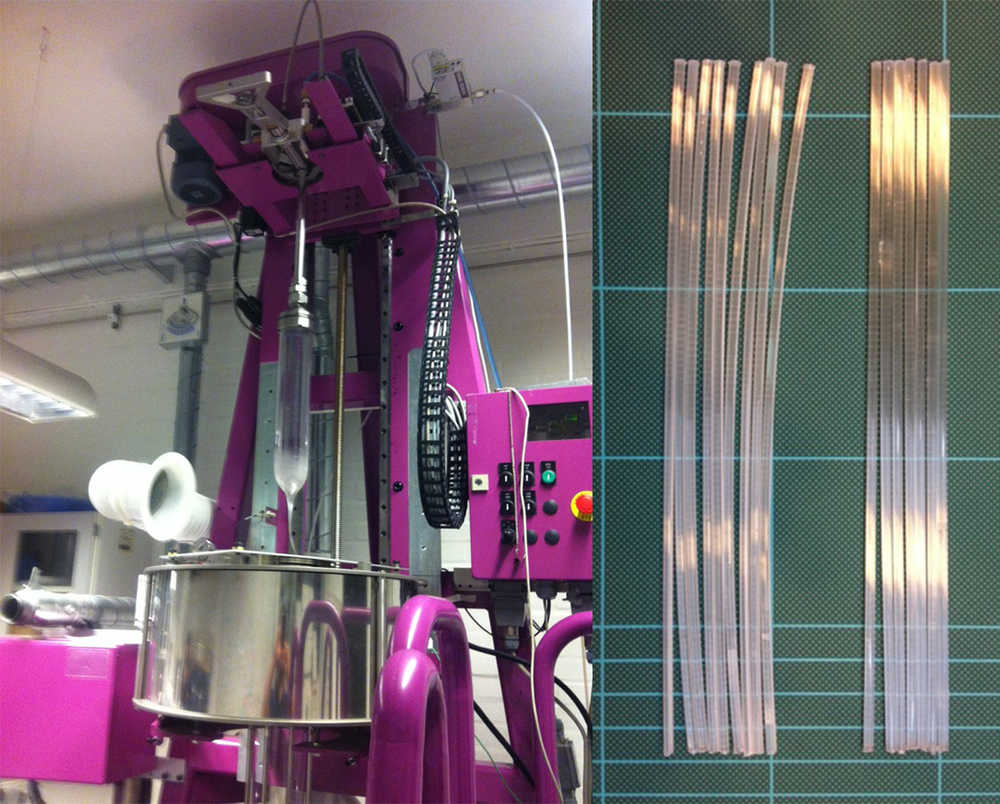

The concept employs a combination of high-strength concrete and light-conducting fibres integrated in the elements through an innovative production process, thereby forming a translucent building material with substantial flexibility and numerous capacities. In order to achieve the desired thermal insulating properties, the concept of sandwich construction is utilised with a core of insulating material through which the optical fibres pass. This provides a degree of stability during the production process.

The combination of materials forges a unique set of thermal properties and high structural strength. These elements may eventually have the capacity to be load-bearing and thus provide an energy effective building envelope material. This signifies the creation of a novel material that bears not only unique physical parameters, but also important aesthetic, tactile and cultural characteristics with significant market potential for companies in the construction and creative industries.

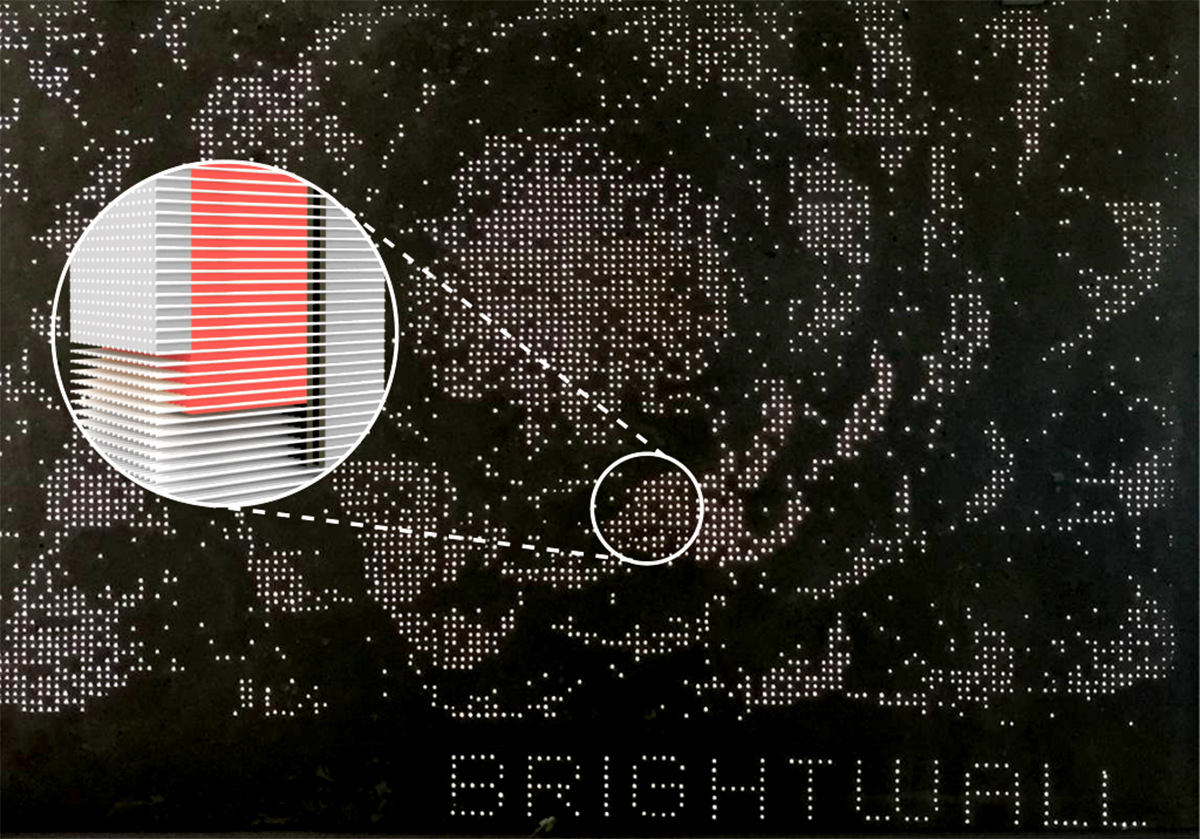

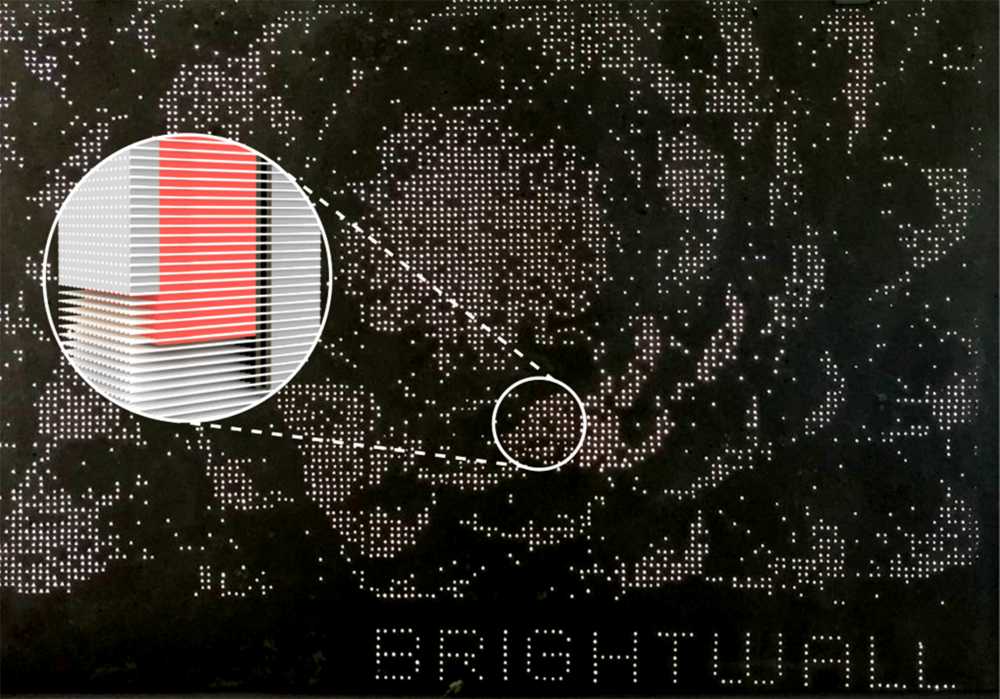

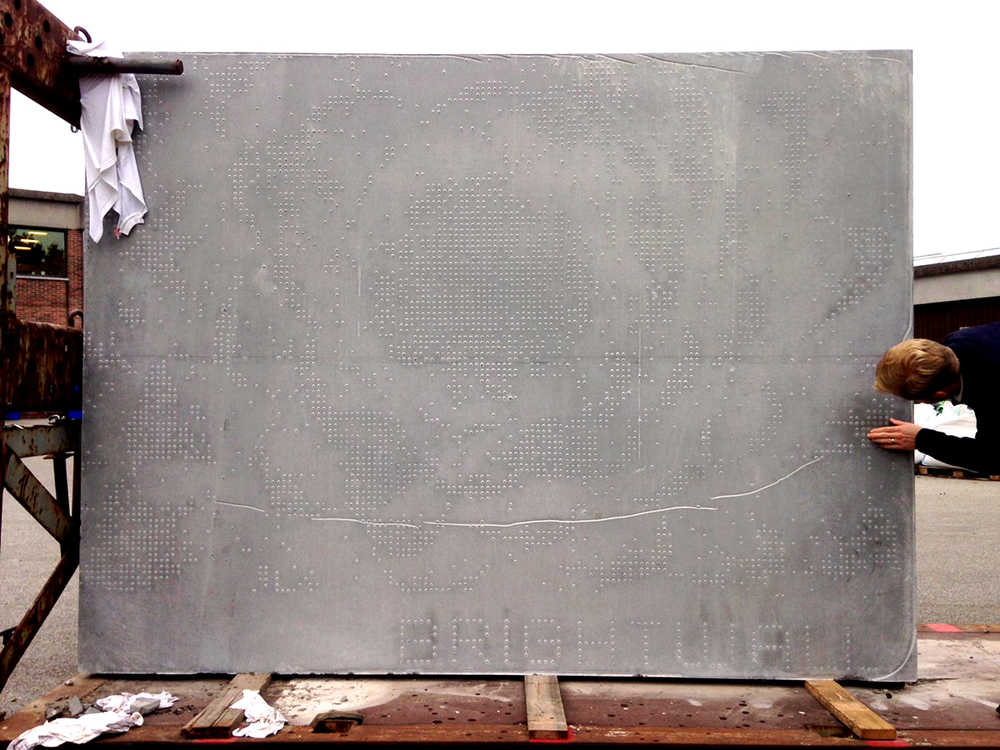

The aesthetic and graphic possibilities of the concept are numerous. UNStudio explored many of these possibilities with the understanding that the system can play a dual role of supplying daylight and thermal comfort during the day while providing outward signage when lights are on at night. The production process now allows a ‘pixel pitch’ down to 20mm.

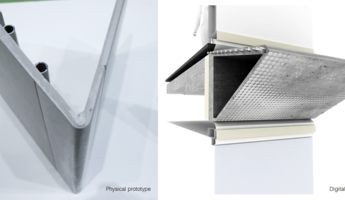

The BrightWall team created a prototype panel under factory conditions using the production process designed for the project. The prototyping gives a positive indication of the production concept, which can be produced with standard contemporary techniques, and the feasibility of upscaling with full digital processes.

UNStudio Team: Haoxiang Yang, Rob Henderson, Filippo Lodi, Valentin Goetze, Wael Batal, Luke Tan, Thys Schreij, Michelle Gulickx

Partners:

Danish Technological Institute (Denmark) - Coordinator

Agencia Estatal Consejo Superior de Investigaciones Científicas (Spain)

Centre d'Etudes et de Recherches de I'Industrie du béton (France)

Confac A/S (Denmark)

Danmarks Tekniske Universitet (Denmark)

Dupont Lightstone ApS (Denmark)

Ecochoice SA (Portugal)

Polymer Optics Ltd (United Kingdom)

UNStudio (The Netherlands)