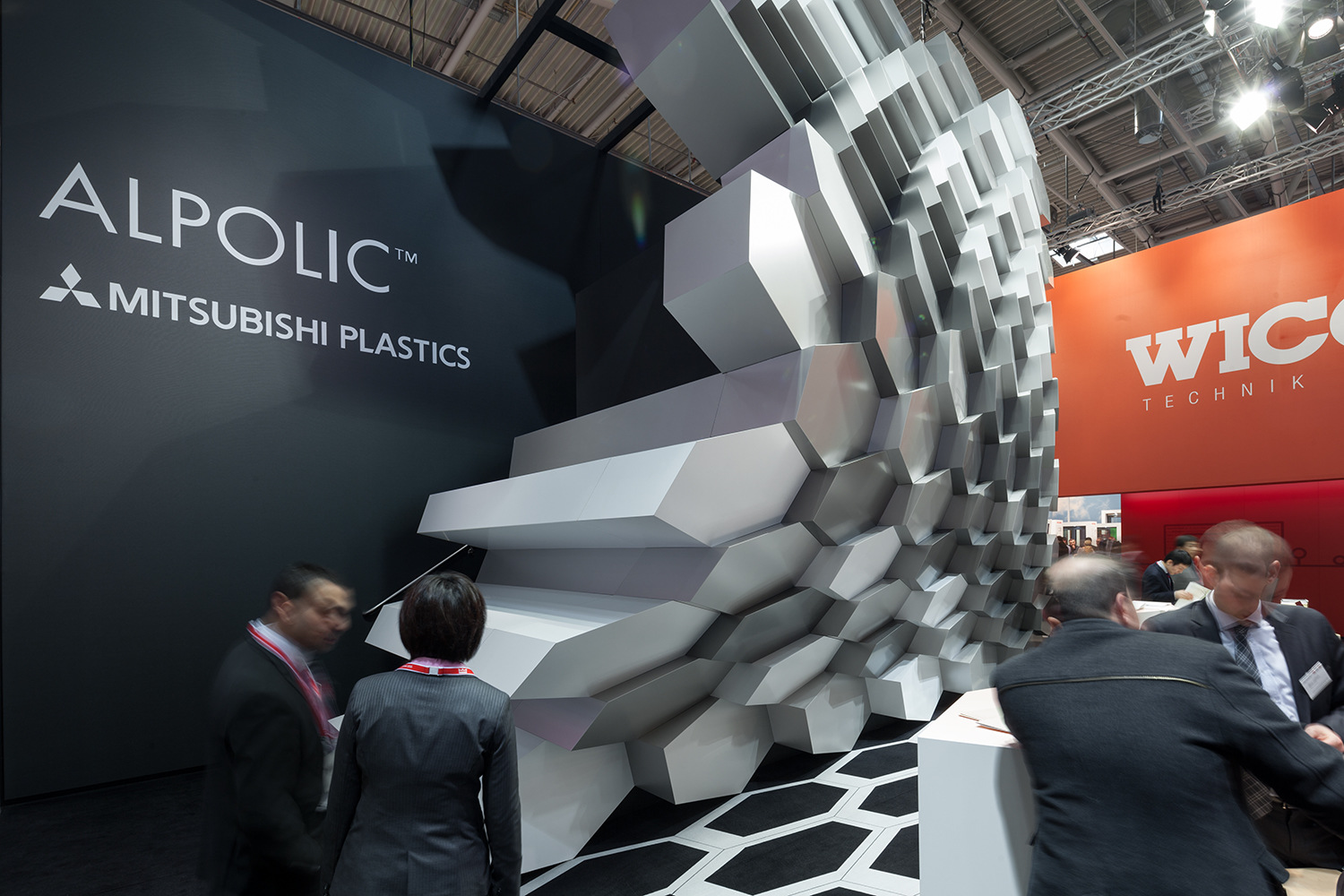

Collaboration with Sorba: Mitsubishi ALPOLIC Fair Stand

Based on our previous experiences collaborating with Sorba, Mitsubishi Plastics invited us to design their ALPOLIC stand at the ‘BAU 2015’ building fair in Munich that ran from 19 – 24 January 2015. At the fair, we elaborated on the principles of smart programming on a bigger scale, resulting in an ALPOLIC wall that acted as a big gesture as well as the main feature of the stand. Sorba pre-manufactured the wall in their factory in The Netherlands and shipped it in parts to the fair. Both the wall and the rest of the stand components were constructed based on UNStudio’s 3D models.

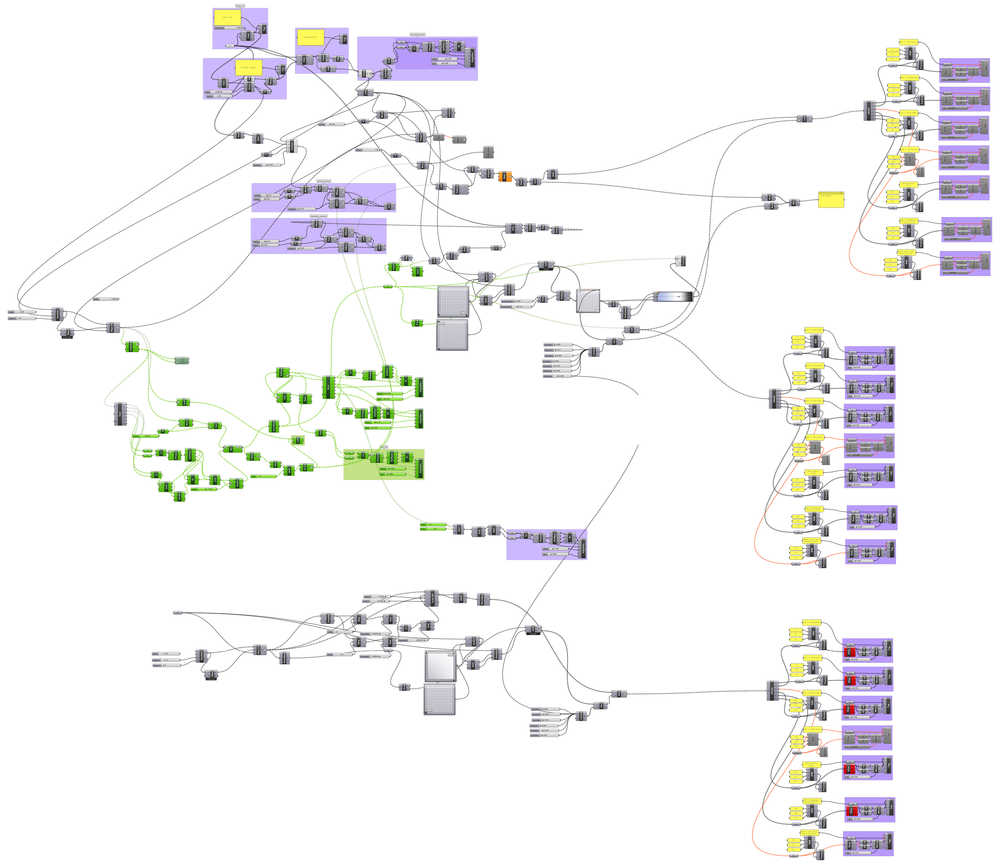

The structure consists of 90 unique hexagonal components interpolated on a double-curved surface. By controlling the horizontal spacing of the surface subdivision, we were able to minimise distortion of the surface mapping and achieve better interlocking of the surface cells. By maintaining the planarity, or flatness, of the cell components, avoiding material twists and reducing the length of the cutting/engraving perimeter, we were able to reduce production costs while achieving elegance in the final piece. We cut each cell out of four-millimetre-thick ALPOLIC sheets that did not exceed 1.5 metres in width. A wooden waffle structure supported the resulting ALPOLIC surface and acted as an alignment mechanism for the final assembly.

By keeping most of the documentation in a digital, parametrized component-based model, we reduced the amount of trial and error in the design process and were able to better communicate our ideas and visions with Sorba. This also made it possible to reduce working time to four weeks of production and fabrication, and only two days of on-site assembly.

Team: Alexander Kalachev, René Wysk, Roman Kristesiashvili, Filippo Lodi